Why are you filtering?

Filtration is a routine, simple, cost-effective means of increasing the life of chromatography consumable accessories. A basic HPLC system includes a solvent cell, pump, injection valve, column, detector, and data logging system. Particulate matter and microbial growth, if not effectively removed by filtration, can interfere with nearly every system component.

1. Filtration of Mobile Phase

Mobile phase filtration can reduce the possibility of column sieve blockage, fitting contamination, pump valve damage, capillary blockage, poor peak shape, impurity peaks, and increased noise.

2. Protection of the Pump

The pump is the most important single component of an HPLC system, and common problems include check valves, pump seals, blockages, and leaks. Resulting in increased baseline noise, non-reproducible retention times and increased pressure. A check valve controls the direction of solvent flow through the pump head and ensures constant pressure. The presence of particulate matter will cause the check valve to leak, affecting flow rate and pressure. The pump seal is always in the process of consumption and wear. Compared with other accessories, it is more prone to wear and tear. It cannot provide high pressure for the system, the pump head will leak, and the retention time will change. Also, gasket debris can contaminate the system. If the mobile phase evaporates and the buffer salts crystallize, this will rapidly wear down the pump seals. Filtration of the mobile phase, therefore, increases the life of the pump seals.

3. Protection of Sample Injection Valve

When the injection valve is working, the rotor surface of the valve rotates with the stator surface, which promotes the conversion between the microchannels on the surface, thereby realizing the functions of LOAD and INJECT. The presence of particles can cause damage to the design surface during rotation, resulting in leakage or blockage. Loops can also become clogged, increasing system pressure, making injection difficult and reducing peak areas. For autosamplers, ensuring the sample is particle-free is critical to preventing blocked needles. Filtration of samples and mobile phases, as well as in-line filters, are effective maintenance of injection valves and columns.

4. In-line Filtrationvs Guard Column

In-line filtration is an ideal protection method, because system wear is inevitable, such as debris caused by continuous wear of pump seals and injection valve seals. Generally, the replaceable sieve plate of the in-line filter has a pore size of 0.5 μm and 2 μm.

Protects against chemicals and particulates that can cause column frit plugging, column head collapse, and loss of column efficiency. The guard column retains strongly retained, irreversibly adsorbed compounds, but its 2 μm sieve is not sufficient to remove particulate matter. The filtration of samples and mobile phases can maintain the adsorption capacity of the guard column for chemical pollutants and can maintain column efficiency for a longer period of time.

5. Chromatographic Column

Chromatographic column problems are mainly chemical adsorption, particle clogging and column bed collapse. Chemisorption is protected by protection. Collapse may be caused by filler dissolution or a sudden increase in pressure. If the peak shape is severely tailed, and fragmented, and retention times do not change, then a clogged frit or collapsed column head is likely the cause.

To protect the column and system, recommended routine maintenance:

1. Filter the mobile phase with a membrane filter;

2. Filter the sample with a syringe filter.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

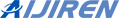

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

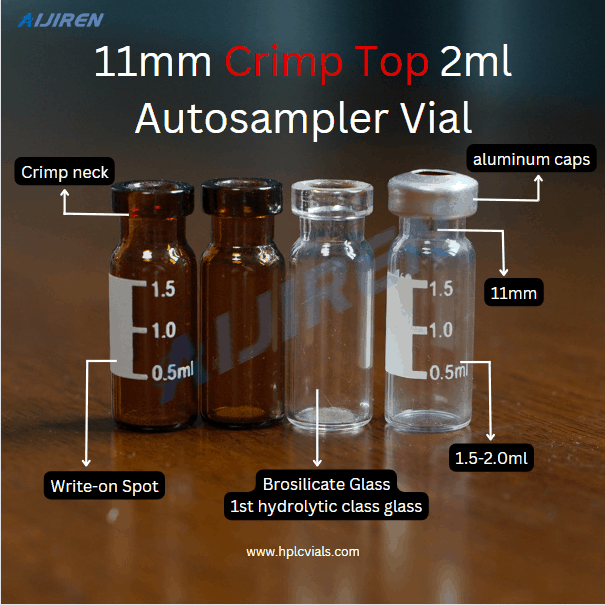

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

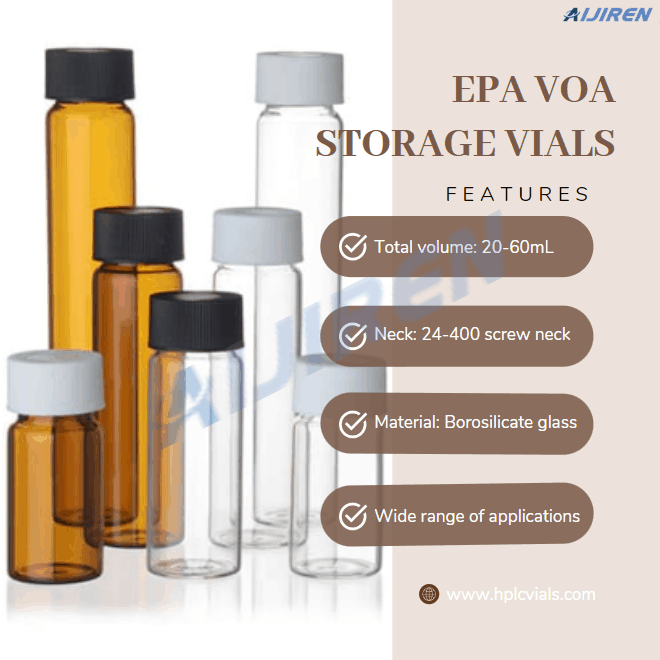

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines