One of the “Three Key Points” for HPLC Instrument Operation: Filtration(1)

Any particulate matter entering the HPLC system will be blocked by the sieve plate at the inlet end of the column. The final result will be blockage of the column, which is characterized by increased system pressure and deformation of the chromatographic peaks. Therefore, various preventive measures should be taken, including operating procedures and various filtration designs of commercial instruments themselves, in an effort to prevent or reduce particulate matter from entering the HPLC system, thereby extending the service life of the instrument and chromatographic column, and improving the reliability of data. In HPLC systems, there are three main sources of particulate matter: the mobile phase, the sample being measured, and wear and tear of instrument system components.

1. Mobile phase

If the mobile phase consists exclusively of HPLC grade solvents, there is no need to filter the mobile phase. This is because high performance liquid chromatography grade organic solvents, such as acetonitrile, methanol, etc., have been filtered through 0.2 µm microporous membranes during the manufacturing process. Similarly, whether you buy HPLC-grade water or water prepared in the laboratory using an ultrapure water purification system, the last step is to pass through a 0.2 µm microporous filter membrane. However, if any of the buffers contain solids such as phosphate, mobile phase filtration will be a necessary step. Although the buffer salt may be soluble and highly pure, it may still contain particulate matter. For example, when the plastic inner cap of the reagent bottle is capped, the plastic cap and the edge of the bottle mouth will squeeze to produce plastic particles. In this case, one of the added solids may be completely dissolved, but a small number of impurity particles may remain in the mobile phase as residue.

Filtration of the mobile phase through a 0.45 µm microporous membrane is an effective method for removing all particulate matter from the mobile phase. 0.2 µm microporous filters can also be used, but they are no more effective than 0.45 µm microporous filters for this application, and the filtration rate will be slower, especially if the reagents and water used in the laboratory are of poor quality. When it’s too good. It is recommended that laboratories draw upon the regulations of similar international laboratories when formulating their standard operating procedures (SOPs) for mobile phase preparation, namely:

Filtration is not required when only HPLC grade liquids are used for mobile phase preparation, whereas all mobile phase components must be filtered before use.

It is also important to use a sinking filter (common materials include fused glass sand core filter plate and microporous metal) at the end inlet of the infusion tube connecting the liquid storage vial and the pump. The specification of this filter is ≥10 µm microporous material, so it cannot replace the mobile phase filtration step, but it can remove dust in the system and ensure the reliability of the use of liquid storage bottles and infusion tubes.

2. Sample to be tested

The second source of particulate matter in liquid phase systems is the sample being measured. Some laboratories filter all samples through a 0.45 µm syringe filter before placing their samples on the autosampler tray (or injecting manually). This is an effective method to remove particulate matter from the sample being tested. But there is one thing that needs attention in this process: if you use a syringe filter, it is impossible to get 100% of the tested samples that pass through the filter, and there will always be more or less loss. Loss comes from the following aspects: adsorption of the filter membrane, adsorption on the particles filtered out by the filter, leakage at the connection between the syringe membrane filter and the syringe, etc. If there is any loss, will the content or concentration of the analyte in the filtered liquid still be the same as that of the original basic sample liquid? This problem generally needs to be confirmed experimentally. Confirming this step will increase the workload and cost. The use of filters is a kind of consumption, and the price of each filter ranges from a few yuan to more than ten yuan. However, when analyzing residues in food, since most matrices are complex, filtration has become an indispensable step. In actual analysis work, each group of samples is generally tested with an external standard, an added recovery or a quality control sample. Therefore, as long as the signal-to-noise ratio obtained during the final test can meet the detection limit requirements, this step can be regarded as Ignored for systematic errors.

Back to List

-

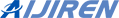

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

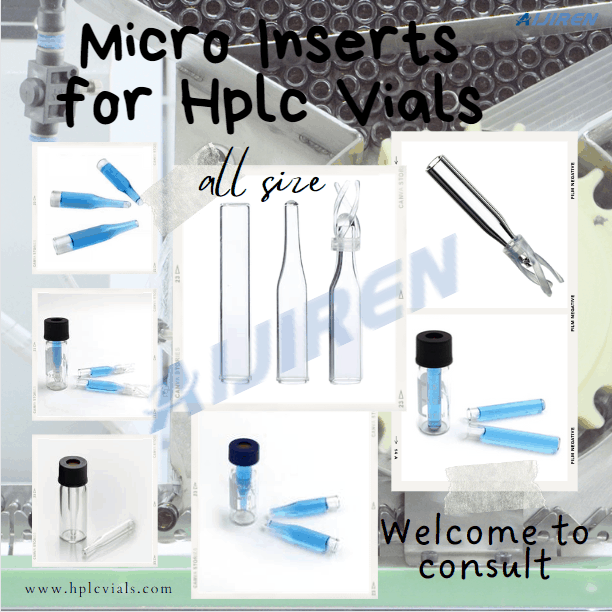

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

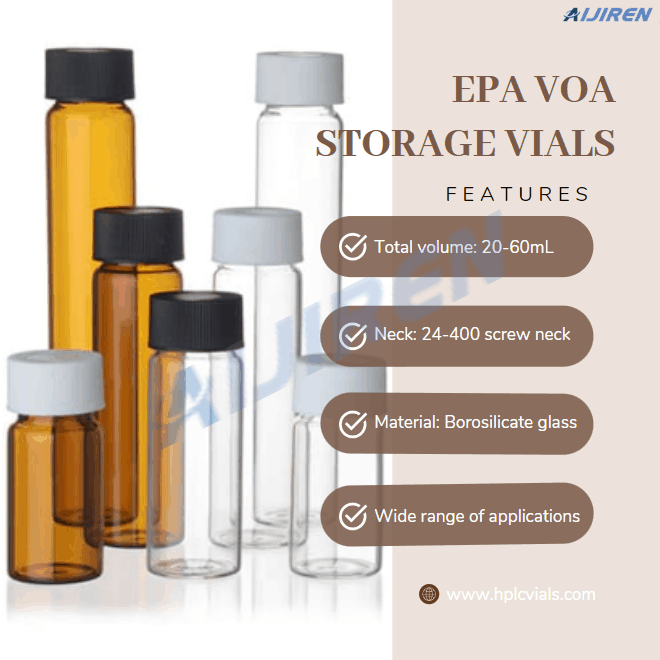

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines