One of the “Three Key Points” for HPLC Instrument Operation: Mobile Phase Degassing

Degassing the mobile phase is a very effective measure to avoid problems with the HPLC system and to obtain ideal data smoothly. It is undesirable to have air bubbles in the system. HPLC pumps must generate a lot of force when transporting liquids. Since the compression ratio of gases is much larger than that of liquids, when bubbles exist, you will observe an instantaneous decrease in flow rate and system pressure. If this bubble is large enough, the liquid phase pump will not be able to deliver any solvent, and if the pressure falls below a preset low pressure limit, the pump will stop working. Some pump designs are good at expelling air bubbles, while others will shut down when air bubbles are present.

When a bubble passes through the infusion pump, due to the high pressure of the system, the bubble usually dissolves in the mobile phase solution and follows the mobile phase through the column. However, the system pressure returns to atmospheric pressure when it reaches the detector flow cell, so bubbles may appear again in the detector flow cell, and irregular burrs will appear on the chromatogram. To solve this problem, some instrument companies design a backpressure controller that provides sufficient pressure at the detector outlet to keep the bubbles dissolved in the mobile phase until they exit the detector. Of course, this pressure cannot exceed the pressure limit that the flow cell can withstand, otherwise the detector may be damaged.

Noise spikes in the liquid chromatogram of an ultraviolet/visible (UV/VIS) detector are often a sign of air bubbles entering and passing through the flow cell. Some detectors are also very sensitive to the presence of air, but exhibit different symptoms than UV/VIS. For example, it has been reported that when using fluorescence (FL) detectors, the presence of dissolved oxygen in the mobile phase may cause some compounds to lose Fluorescence. In addition, electrochemical (EC) detectors that detect changes in current caused by the redox reaction of the substance to be measured on the electrode surface are also very sensitive to the presence of dissolved oxygen in the mobile phase. In addition, the presence of air bubbles sometimes results in non-reproducible retention times.

Therefore, care must be taken to eliminate air in the mobile phase, and air should also be prevented from penetrating into the mobile phase from pipes (such as PTFE tubes).

All of these problems can be avoided or minimized if proper attention is paid to removing dissolved air from the mobile phase before use. Commonly used degassing methods include the following:

1. Helium blowing degassing method: Taking advantage of the fact that the solubility of helium in liquid is lower than that of air, it can be very effectively flowed into the mobile phase liquid storage container at a flow rate of about 60 mL/min for 10 to 15 minutes under a pressure of 0.1MPa. Excluding dissolved air from the mobile phase can eliminate nearly 80% of the oxygen. Using a high-efficiency distributed jet device, one volume of helium can remove an equal volume of nearly all gas from the mobile phase. This means that 1L of helium can be degassed through 1L of mobile phase. Although this degassing method is good, the price of helium in our country is relatively high, and few laboratories use this method.

2. Heating reflux method: This method has better degassing effect. Pay attention to the cooling efficiency of the condensation tower during operation, otherwise the solvent will be lost and the ratio of the mixed mobile phase will change.

3. Vacuum degassing method: This method can use a vacuum pump to reduce the pressure to 0.05~0.07MPa to remove dissolved gas. However, since vacuum degassing will change the composition of the mixed solvent, thus affecting the reproducibility of the experiment, it is mostly used for simple analysis of single-solvent systems.

4. Ultrasonic degassing method: Place the mobile phase to be degassed in an ultrasonic cleaner and oscillate with ultrasonic waves for 10 to 20 minutes. This method has the worst degassing effect.

5. Online degassing method: All current commercial HPLC instruments can be equipped with online degassing machines. Online degassing is simple to use, trouble-free and effective. It is recommended that you must purchase the instrument when purchasing it. Some companies offer it as an optional part, so you should confirm with the instrument company when discussing the configuration.

Back to List

-

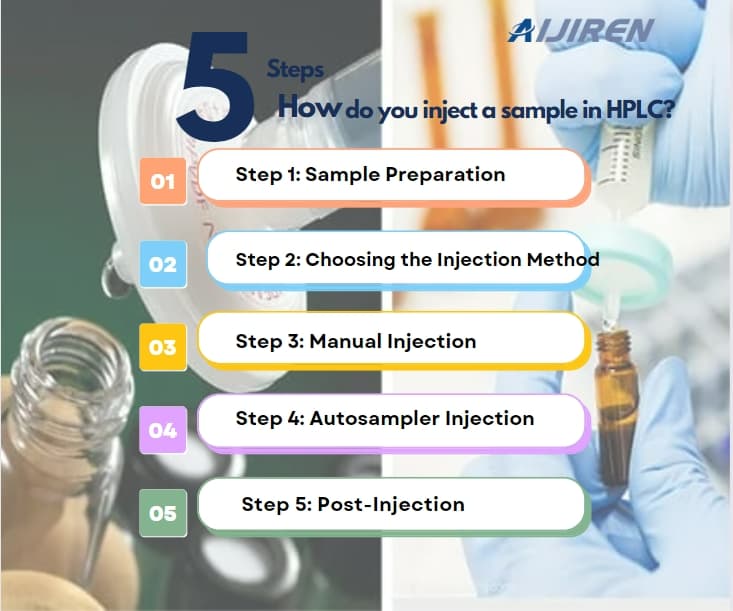

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

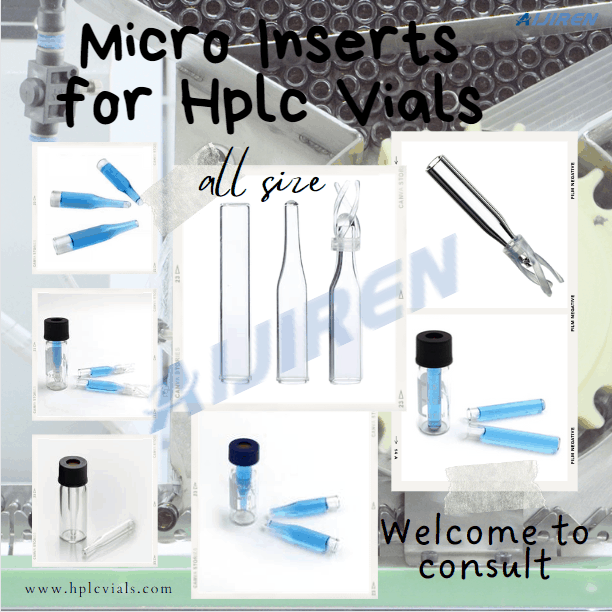

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

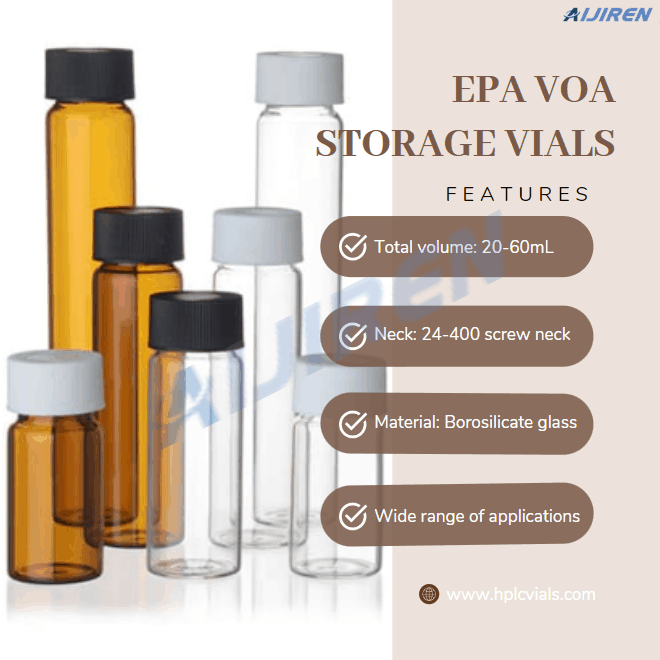

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines