Common faults and solutions of automatic samplers(1)

The main components of the autosampler are the injection needle, needle seat seal, injection valve and syringe. If maintenance is improper or not timely, the injection needle will easily bend and produce burrs, and the needle seat and injection valve will leak and become clogged, resulting in abnormalities such as ghost peaks, residual peak reproducibility, and insufficient quantitative analysis reproducibility. The syringe will produce bubbles, resulting in inaccurate injection. Therefore, regular maintenance of the automatic sampler is an important guarantee for us to do a good job in liquid phase analysis. So how should the maintenance of the automatic sampler be done?

1. The baseline is unstable and ghost peaks increase.

Phenomenon: Fig1 a and Fig1 b analyze the same standard. Fig1 a has an unstable baseline and increased ghost peaks; while Fig1 b has a stable baseline and is a normal spectrum.

Reason: After ruling out pump, mobile phase and detector problems, this phenomenon indicates that the sampling system is contaminated.

Solution: Use 5% perchloric acid aqueous solution to replace the original autosampler cleaning solution, use a syringe to aspirate about 100mL, put the above cleaning solution into the sample vial, and use a plastic damping tube to replace the chromatographic column. The outlet of the damping tube is connected to the waste liquid and not to the detector. Turn on the pump and set a regular flow rate. Set the automatic injection program with a sample volume of 200 μL, an analysis time of 1 minute, and 20 consecutive times. After completion, replace the cleaning solution with pure water, fill the sample bottles with pure water, and follow the same operations as above. (Considering that the injection volume is large and the number of repetitions is high, prepare 5 sample vials containing appropriate amounts of liquid and place them in the sample tray. , set the automatic sampling program, each bottle is pumped 4 times continuously, and the 5 sample bottles are pumped 20 times in total to avoid emptying).

Note: 5% perchloric acid aqueous solution can effectively remove dirt in the system. If there is no perchloric acid, you can use methanol or pure water to clean it multiple times with a large injection volume to achieve the same effect.

2. The pump pressure suddenly drops to 0 or very small

Phenomenon: During a continuous sample analysis process, the system was normal at the beginning of the analysis, but when the eighth sample was analyzed, the pump pressure suddenly dropped to 0.3Mpa, while the normal pump pressure was 5.5Mpa. I smell methanol in the injector (there is a lot of methanol in the mobile phase). I opened the injector door and found liquid dripping out of the pipe under the drain valve, smelling of methanol. I stopped the system and pressed shift+9 and found that the inlet and rinse port were salting out badly.

Reason: The injection port is blocked, and the mobile phase cannot enter the chromatographic column and leaks out, causing the pump pressure to drop.

Solution: Perform routine maintenance on the autosampler

Replace the injection septum and Septumcutout (if there are no spare parts, the injection port seal and rinse port septum should be super washed with pure water → methanol.) Use lens cleaning paper dipped in pure water to wipe off the salt next to the inlet and rinse port. Analyze and then scrub with methanol. Install the two components, open the machine for debugging, and check that there is no leakage and the pump pressure is normal.

3. Poor injection reproducibility

reason:1) The metering pump is inaccurate; 2) The six-position valve is worn.

Solution: 1) Determine the accuracy of metering pump suction. Put enough pure water into the sample vial, wipe off the water outside, weigh it with an analytical balance, record the reading W1, put it in the injection tray, set the injection program, the injection volume is 100 μL, ten times in a row, after Wipe the water on the surface of the sample bottle with filter paper, weigh it on a balance, and get the reading W2. The value obtained from W1-W2 should be the mass of 1mL of pure water at the corresponding temperature. If the difference is not big, the metering pump is fine. If there is a problem with the metering pump, there may be a problem with the plunger rod or sealing ring of the metering pump.

2) The six-position valve is worn. According to the manual of the automatic sampler, remove the six-position valve and observe whether the three ports are worn. If the wear is serious, replace the six-position valve with a new one. According to the operation in the book, assemble and debug it, and the reproducibility is good.

Back to List

-

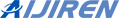

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

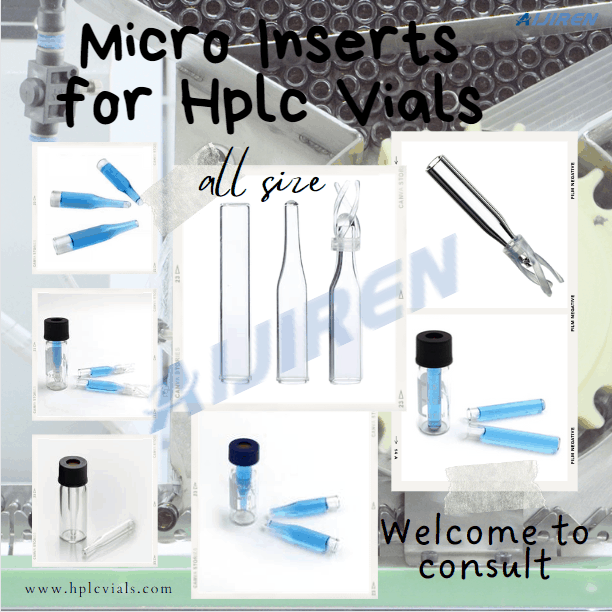

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

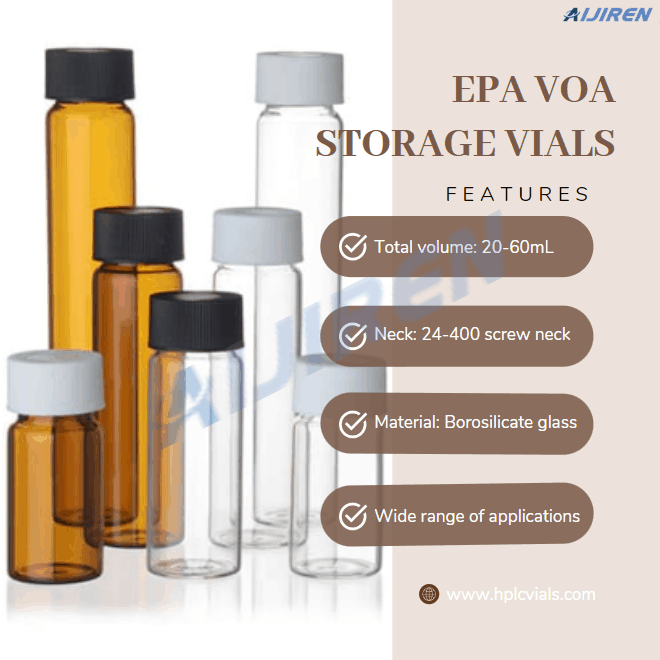

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines