How does LC column packing affect column energy?

The performance of LC columns depends primarily on the nature and type of packing. The size, shape, bonded phase, carbon content, etc. of the packing can all affect the performance of the liquid chromatography column, which is very helpful for our use and selection of chromatography columns.

1. Influence of particle size

The smaller the average particle size of the liquid chromatography column packing, the smaller the eddy current diffusion, the better the mass transfer and the higher the column efficiency. However, small packing particle size results in poor permeability and high column pressure. At the same time, the wider the particle size distribution of the filler, the worse the permeability and the lower the column efficiency of the chromatographic column. Common filler particle sizes are 3μm, 3.5μm, 5μm, 10μm, etc.

2.Influence of Particle Shape

The packing materials of liquid chromatography columns are divided into amorphous and spherical types. The liquid chromatography column made of amorphous packing has uneven bed structure, uneven linear velocity of the mobile phase, and the peak shape of the chromatogram is wider; the liquid chromatography column made of spherical packing has a uniform bed structure, so the chromatographic column efficiency is high, good reproducibility. Spherical packing is currently the most common liquid chromatography column packing, which has better performance and reproducibility.

3. Influence of the Bonding Phase

Silica gel is used as the matrix, and C18, C8, amino, cyano and other groups are chemically bonded to the matrix as the packing in the liquid chromatography column. By bonding different chemical groups, liquid chromatography columns with different properties are obtained. Due to the different separation mechanisms of the different bonding groups, the retention and separation of compounds are affected.

The bonding of the filler makes the stationary phase of the liquid chromatography column relatively stable and difficult to lose. At the same time, the adverse effects of silicone hydroxyl groups are largely eliminated. It can be used in a variety of mobile phases and is widely used. However, the bonded filler has poor acid resistance and the pH cannot be less than 2. When the pH of the mobile phase exceeds the acidic range, the bonded phase is easily lost and the durability and stability become worse.

4. Influence of End Group Sealing

Silica gel is widely used as a packing matrix material for liquid chromatography columns due to its special surface chemical properties. The surface of silica gel has silanol groups. The density, distribution and chemical properties of the silanol groups will affect different types of chromatographic behavior to varying degrees.

When using high-performance liquid chromatography columns based on silica gel, especially reversed-phase chromatography columns, non-specific adsorption due to free silanol groups (or silanol groups) is often encountered. For some highly polar solutes, such as alkalis, the chromatographic peak will be strongly tailed and may even fail to elute due to strong adsorption. End-capping is usually used to reduce the influence of silanol groups. The specific method is to perform a subsequent reaction between the filler and a small silane (such as trimethylchlorosilane) to react off some of the residual silanol groups to increase surface coverage. This method can not only reduce irreversible adsorption or tailing, but also increase the carbon content. However, this method cannot completely react the remaining silanol groups, and 50% of the silanol groups remain unreacted.

5. Influence of Carbon Content

The carbon content of liquid chromatography column packings, especially reversed-phase packings, is often used to characterize the degree of surface chemical modification. Carbon chains are usually introduced into fillers by bonding. The higher the carbon content of the packing, the higher the carbon chain density, the longer the carbon chain, the higher the capacity factor, and the higher the hydrophobicity. Under reversed-phase conditions, the carbon chain grows, which means that the filler has a larger specific surface area, association is enhanced, and retention of the analyte is increased. Therefore, liquid chromatography columns with high carbon packing have good stability and repeatability, which is beneficial for the separation of compounds with poor retention effects and can improve the tailing of polar compounds; liquid chromatography columns with low carbon packing are beneficial for the analysis of neutral and basic compounds and can reduce solvent loss.

In addition to the above, the activity, impurity content, pH stability, thermal stability, etc. of the silica gel packing will also affect the performance of the liquid chromatography column.

When silica gel is produced, the processing temperatures are different and the activity of silica gel is also different. The activity of silica gel is the main source of selectivity differences and mainly affects the retention behavior of basic compounds; the impurity content of silica gel is an important indicator of the quality of the chromatography column. The content of heavy metals is low, the activity of silanol groups is low and the tailing is reduced.

Back to List

-

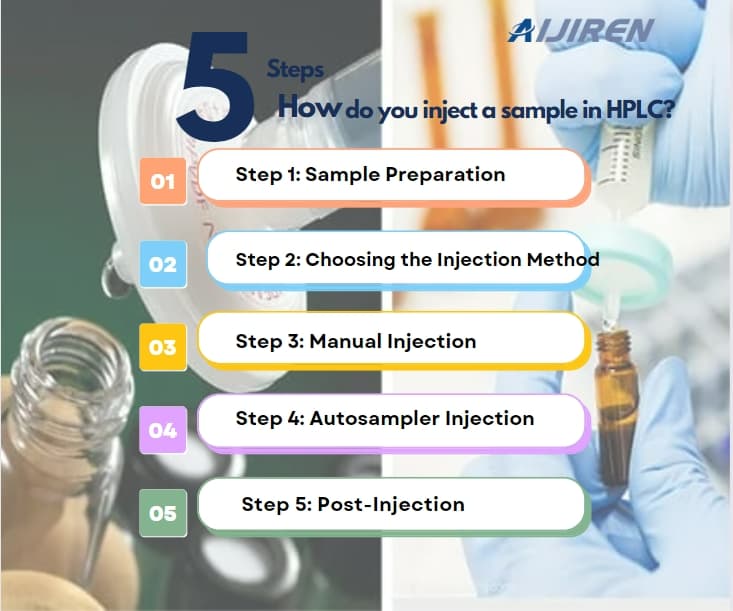

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

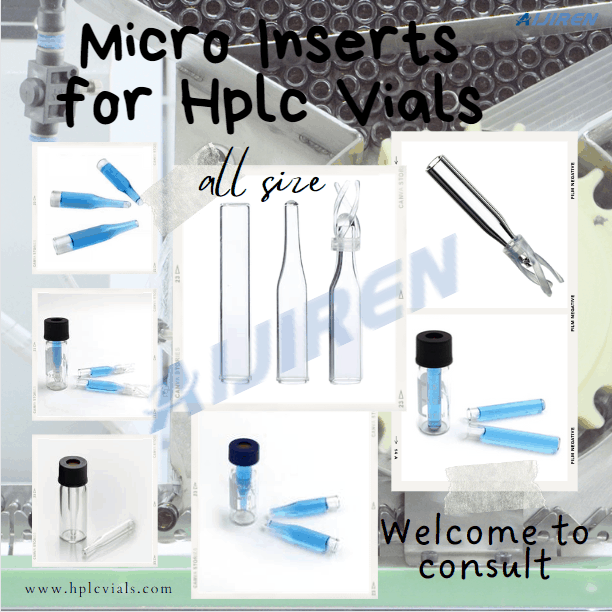

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

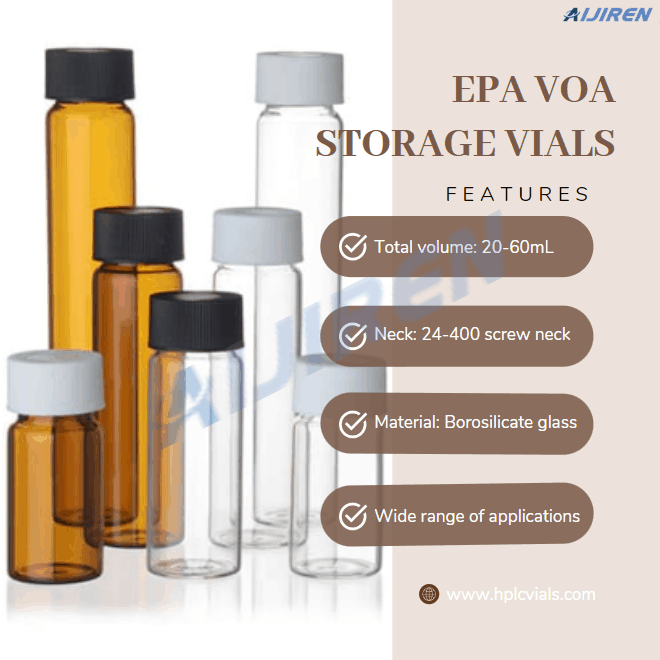

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines