Causes and Solutions of Gas Chromatography Peak Tailing(Ⅲ)

When analyzing compounds with gas chromatography (GC) and gas chromatography-mass spectrometry, sometimes you will encounter the problem of chromatographic peak tailing, which is mainly analyzed from the following aspects:

chromatographic column problems

Chromatographic column type issues

Chromatographic column type issues

The gas chromatography column used is not suitable for sample analysis. If the sample is polar and a non-polar or weakly polar chromatographic column is used, the chromatographic peak tailing will be serious. In this case, the column needs to be Just change to a polar or highly polar column.

The chromatographic column is not installed in place

The chromatographic column is not installed in place

There are length requirements for the chromatographic column installed at the inlet end. Generally, Aijiren chromatographs require the column to expose 4-6mm of the column nut of the inlet. When using the EI source, 1-2mm is required to be exposed at the mass spectrometer end. When using the CI source, the mass spectrometer end requires 0-1mm to be exposed.in addition, different liners will have different requirements for the exposed length of the chromatographic column. If the column is too long outside the column nut, it will prevent the sample from entering the column quickly, causing peak tailing. If the distance between the capillary column and the gas chromatograph detector FID/NFD/FPD nozzle is too short, it may also cause peak tailing.

The temperature of the chromatographic column

The temperature of the chromatographic column

The temperature of the chromatographic column is controlled by setting the temperature of the column oven. An appropriate temperature can obtain good resolution and peak shape. Gas chromatographs generally use programmed temperature rise to separate compounds. The starting temperature of the programmed temperature rise is required to be lower than the boiling point of the earliest compound to flow out. For low boiling point compounds, the initial temperature of the programmed temperature rise can be set to 10-25°C below the boiling point of the solvent. If a compound with a high boiling point appears tailing, the peak temperature of the compound can be appropriately increased.

The chromatographic column is contaminated

The chromatographic column is contaminated

If the chromatographic peaks of a chromatographic column when analyzing a sample are all normal at first, but after using it for a period of time, the chromatographic peaks are obviously tailed, in this case the column may be contaminated. When a chromatographic column is contaminated, the column efficiency will decrease, resulting in chromatographic peak tailing.

Solution:

Solution:

Step 1: Clean the column

The polar organic solvent methanol and the non-polar organic solvent n-hexane can be used to enter the gas chromatograph alternately without running the mass spectrometer detector to allow the organic solvent to clean the chromatographic column.

Step 2: Conditioning the Column

Set the temperature of the column oven to be higher than the maximum temperature in the chromatographic method and lower than the maximum tolerable temperature of the chromatographic column. Keep it for 3-4 hours, and then test the sample again to observe whether the chromatographic peaks have improved.

Step 3: Cut off the column

After using the first and second steps, if the problem of chromatographic peak tailing is not significantly improved, you can cut off at least 20 cm of the chromatographic column connected to the injection port. If the chromatographic column is contaminated, most of the contaminants will be concentrated at the inlet end, so the chromatographic column at the inlet end can be cut off by at least 20 inches; if the contamination is serious, the cutoff length can be longer.

Back to List

-

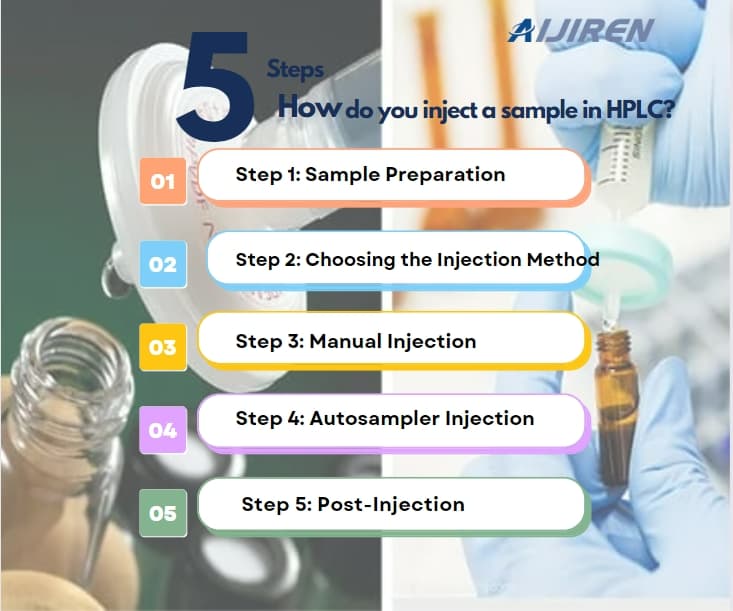

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

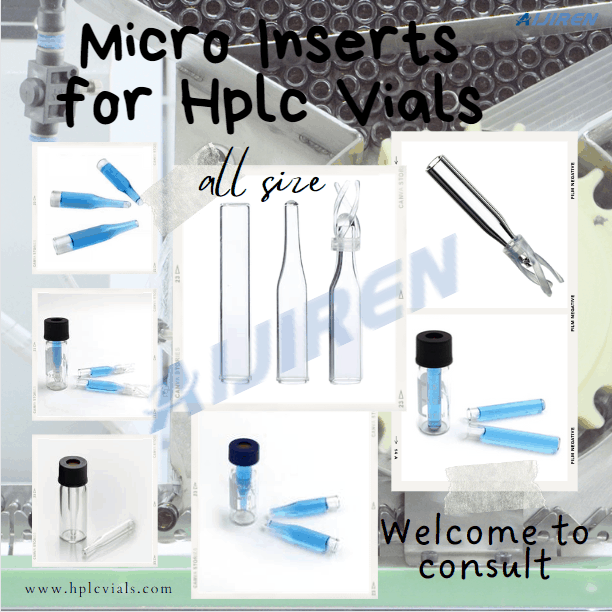

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

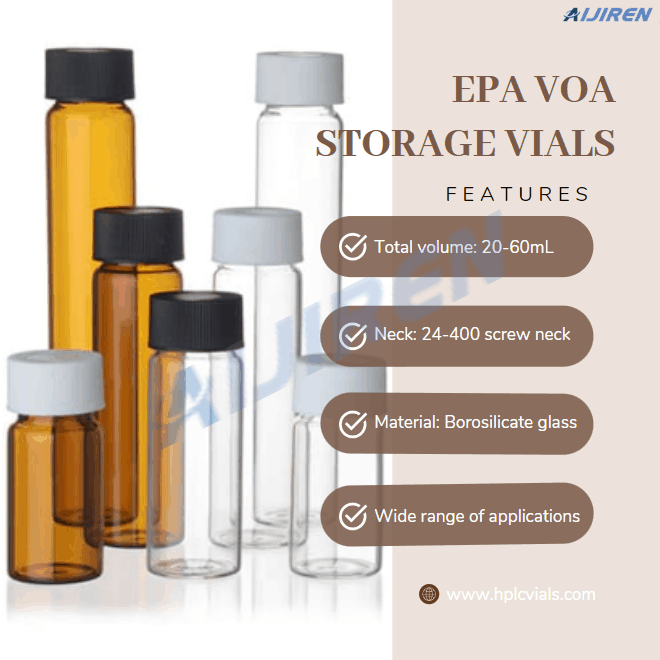

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines