What is the difference between PVDF and PTFE?

The key difference between PVDF and PTFE is that PVDF has comparatively a low density, whereas PTFE has comparatively a high density.

The term PVDF stands for polyvinylidene fluoride, while the term PTFE stands for polytetrafluoroethylene. Both these are industrially important polymer materials consisting of a large number of monomer units.

What is PTFE?

Polytetrafluoroethylene (PTFE), commercially known as Teflon, is a semi-crystalline fluoropolymer. PTFE is well-known for its application as a non-stick coating for kitchen pots and pans due to its exceptional heat and corrosion resistance. Besides this, these properties have proven beneficial in other industries too, namely the automotive, chemical and medical industries, where chemical inertness, electrical insulation, and long service life are especially valuable.

PTFE has been the dominant fluoropolymer with a significant amount of market growth in recent years and is expected to gain yet more popularity in the coming years. The global revenue for PTFE is expected to reach more than US$7bn by 2022, and the demand is estimated to be as much as 247,000 megatonnes in the year 2022. This is due to increasing electronic and chemical applications, as well as the emerging application for polymers in photovoltaic modules and fuel cells.

The applications of PTFE

Given that the specific processing of PTFE, including additive manufacturing, can have such a large impact on its properties, there is a large range of applications for this material. PTFE has applications in a huge range of industrial sectors, including automotive, chemical, electronic, aerospace, and medical.

PTFE Sheet and Film

Given PTFE has such a high melting point for a polymer, it is commonly used to produce sheets and films for further applications. Sheets and thin films of PTFE are used mainly in the packaging sector. In the packaging of chemical equipment, pharmaceuticals, and cosmetic products, chemically inert material such as PTFE is worth the extra cost in comparison to other commodity packaging materials.

Industrial Coating

The most frequent application of PTFE globally is in industrial coatings. It has a very low friction coefficient and high-temperature resistance, making it perfect for demanding conditions. Interestingly, PTFE lubricant is used in the construction of igniters for rocket propellants, and to coat certain types of bullets to reduce wear on the inside of the barrel. Other uses include coatings for hoses subjected to corrosive environments and low-friction coatings on windscreen wipers and hair straighteners. Teflon coatings and non-stick wear are used on kitchenware to prevent food from sticking to pots and pans.

PTFE Powder

Fine PTFE powder can be paste extruded into useful shapes such as tapes, wires, and tubes. These are mostly used for the insulation of wires and cables, tubing, pipe liners, and films. PTFE powder can also be used as a powder coating for some materials, offering a more aesthetic finish.

What is PVDF?

PVDF is a semicrystalline, thermoplastic polymer. Its degree of crystallinity varies in the range of 35 – 70%, depending on the method of preparation. What makes it special is that it has a unique combination of mechanical and electrical properties (i.e., piezoelectricity), retains high standards of purity, and possesses high resistance to most chemicals including solvents, acids, and hydrocarbons.

With the chemical formula (CH2=CF2)n, PVDF sits in the middle between polyethylene (PE: (CH2=CH2)n ) and polytetrafluorethylene (PTFE: (CF2=CF2)n ). Its simple chemical structure gives it the flexibility of PE and some of the stereochemical constraints of PTFE. The different molecular and crystal structures of PVDF change depending on the preparation of the samples.

The complex crystalline polymorphism of PVDF cannot be found in other synthetic polymers. There are five known crystalline forms in PVDF: alpha, beta, gamma, delta, and epsilon. The beta phase is the most commonly used form, and together with the alpha and gamma phases constitutes the major phases:

1. The alpha phase is nonpolar and is generated in the melting process from melt crystallization at any temperature.

2. The beta phase is an oriented phase that results from the mechanical deformation of the specimen via uniaxial or biaxial mechanical drawing below 70 °C. It is the most used for piezoelectric applications.

3. A gamma phase is a special form that develops under specific circumstances. It can be generated through crystallization at temperatures close to the melting point of the alpha phase via melt casting or solution casting.

The applications of PVDF

Some of the most common applications of PVDF components include:

1. Filaments for additive manufacturing

2. High purity semiconductors

3. Wire and cable isolators

4. Biomedical, artificial membranes

5. Nuclear waste processing

6. ipe and pumping applications

7. General chemical processing

8. Water treatment membranes

9. Food and pharmaceutical processing

10. Battery and sensors

11. Architectural coating

What is the difference between PVDF and PTFE?

PVDF and PTFE are short terms for polyvinylidene fluoride and polytetrafluoroethylene, respectively. The key difference between PVDF and PTFE is that PVDF has comparatively a low density, whereas PTFE has comparatively a high density. Moreover, PVDF is produced via polymerization of vinylidene difluoride, while PVDF is produced via free-radical polymerization.

The following infographic lists the differences between PVDF and PTFE in tabular form.

|

PVDF VS PTFE |

||

| PVDF | PTFE | |

| Definition | PVDF stands for polyvinylidene fluoride | PTFE stands for polytetrafluoroethylene |

| Repeating Unit | (C2H4)n | (CH2F2)n |

| Production | Polymerization of vinylidene difluoride | Free-radical polymerization |

| Density | Comparatively low | Comparatively high |

| Applications | Production of different forms of piping products, sheets, tubing, films, plate, and an insulator for premium wire | Production of the non-stick coating, manufacturing containers and pipes, etc. |

Summary

The big difference between PTFE and PVDF is that PTFE membranes can be used in the filtration of strong acids and aggressive solutions, but PVDF membranes are more suited for the filtration of non-aggressive aqueous and mild organic solutions.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

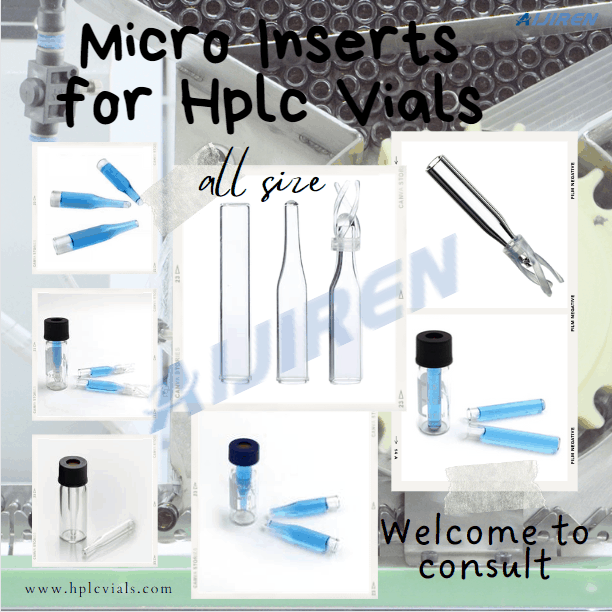

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

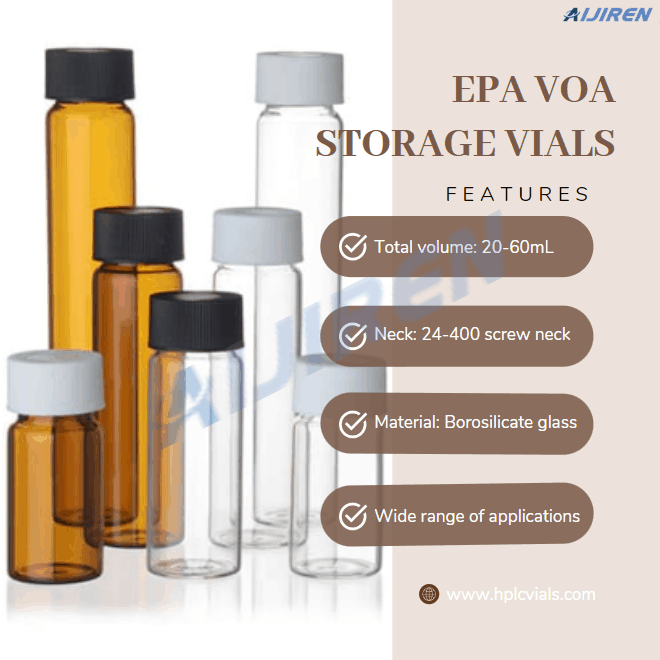

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines