Static Headspace-gas chromatography Sample Introduction Method

Static headspace sampling of gas chromatography is to seal liquid or solid sample solution in a container (balance vial, headspace sample vial), and heat it at a certain temperature (equilibrium temperature) for a period of time (equilibrium time), so that the gas-liquid or The gas-solid two-phase reaches equilibrium, and then the gas phase is taken into a gas chromatograph for analysis. Static headspace sampling is also called balanced headspace sampling or a gas phase extraction sampling.

Static headspace intrductions are available as syringe injections, equilibrium pressurized injections and dosing ring pressurized injections.

1. Syringe injection:

Sampling is done with a syringe. In order to reduce the condensation of volatile components in the syringe, a temperature control device is generally placed outside the syringe. The injector should be purged with gas before each injection to eliminate the memory effect of the system as much as possible.

(1) Features:

Wide applicability, easy to clean.

The pressure is difficult to control, and the accuracy of the injection volume is poor.

When the pressure of the headspace gas is too high under heating conditions, volatile components will be lost at the moment when the syringe is pulled out of the headspace vial.

It is suitable for the analysis of samples with large volatile content such as essence, fragrance and tobacco.

(2) Matters needing attention:

1) The syringe must be heatable:

The temperature of the sample must not change as it is drawn from the headspace vial to the gas chromatograph inlet. Therefore, the syringe must be heatable, otherwise the sample will recondense inside the syringe.

2) Sample volatilization will affect reproducibility:

During the process of aspirating the sample from the headspace vial to the gas chromatograph inlet, the sample will be lost due to the pressure difference between the sample in the headspace vial and the normal pressure. Therefore, it is necessary to set the temperature of the syringe to be higher than that of the headspace vial to minimize the error caused by the pressure difference.

3) Cross-contamination issues:

Continuously purge the syringe with inert gas (nitrogen or helium) between two injections to avoid cross-contamination between samples and avoid ghost peaks.

4) Alignment of the syringe with the gas chromatograph inlet:

Through the precise stepping motor and advanced position memory software system, the accurate positioning of the injector and gas chromatograph inlet is ensured.

2. Balanced pressure injection:

When the volatile components in the sample reach distribution equilibrium, a certain air pressure is applied to the headspace sample bottle to press the headspace gas into the carrier gas flow.

The balanced pressurized sampling system has a small dead volume.

Balanced pressurized injection relies on a time program to control the analysis process, it is difficult to calculate the specific injection volume, and the injection error is relatively large.

3. Quantitative loop pressure injection:

It is composed of a quantitative loop, a pressure control valve and a gas transmission pipeline. By applying a certain air pressure to the headspace sample bottle, the headspace gas is pressed into the quantitative loop of the six-way valve, and then the top space in the quantitative loop is filled with the carrier gas. Air enters the column.

It has good reproducibility and is suitable for quantitative analysis.

Because the system pipeline is long, volatile components are easy to adsorb on the pipe wall, so the pipeline is generally heated to a higher temperature.

In short, there are different sample introduction methods for gas chromatograph static headspace sampling, and you can choose the appropriate sampling method according to your own needs to reduce unnecessary troubles.

Back to List

-

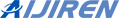

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

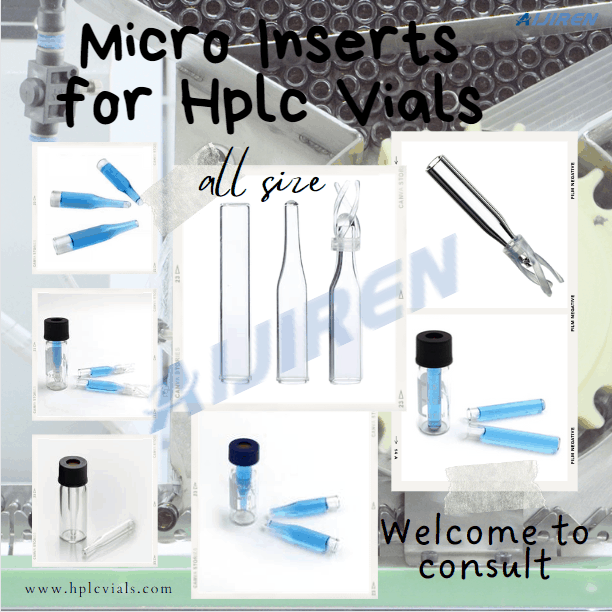

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

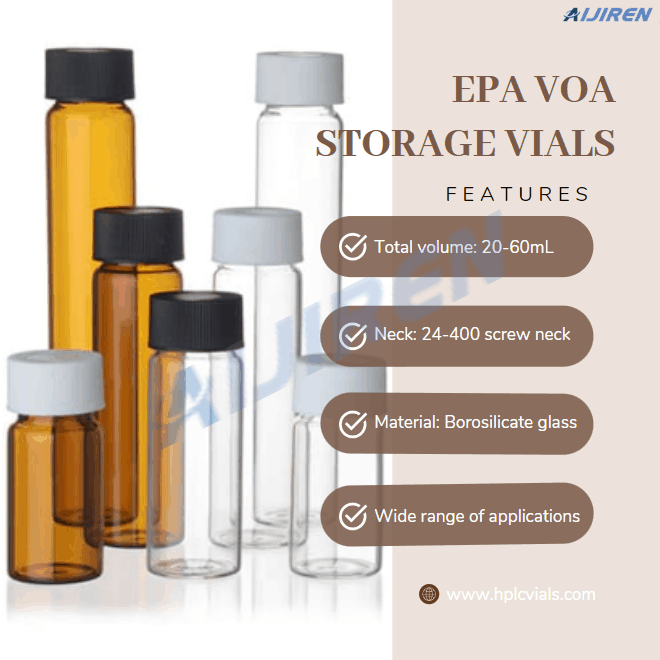

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines