Routine Maintenance of Autosampler

Autosampler failures can sometimes cause headaches. To find out the cause of the fault and effectively solve it, we must first start with daily maintenance and upkeep.

1. Clean the chromatography system in time

After analyzing the sample and cleaning the chromatographic column, use a PEEK tube to connect it to the original position of the chromatographic column, clean it with degassed pure water at a flow rate of 1.5 mL/min for 1.5 hours, and then clean it with methanol under the same conditions. Replace the autosampler cleaning solution with methanol, open the drain valve, use a syringe to aspirate 50 mL, then close the drain valve, purge, and rinse three times each. After completion, press shift, 9, to close the autosampler.

Pure water cleaning of the chromatography system can remove residual buffer salts in the pipelines, and methanol cleaning can prevent the system from breeding bacteria and microorganisms from clogging the pipelines, and can also wash away water-insoluble substances.

2. Replace Septum cutout regularly

Regularly replace the Septum cutout, that is, the rubber pad in the Rinse cap. There is a needle cleaning program in the automatic injection of the analysis sample settings, so the rubber pad can easily become dirty after a period of time. Replace it promptly to avoid contaminating the needle with dirt on the pad.

3. Replace the injection septum regularly

Replace the injection septum regularly. Use a fixed wrench to remove the inlet cap, take out the inlet liner sleeve inside, take off the old injector pad, put the new one in as is, and install it in the inlet as it is, and tighten the nut with your hands. , use a wrench to tighten it another 15°.

4. Apply lubricating oil regularly

Use absorbent paper to clean the oil dirt and garbage on the lifting shaft of the control syringe, apply a small amount of lubricating oil on the lifting shaft, and use absorbent paper to absorb the excess lubricating oil. Test several samples and listen to the clear and regular sound of the lifting shaft when it is working.

5. Clean with pure methanol and do not use the machine for a long time

If the machine is not used for a long time, pure methanol can be used instead of the cleaning solution. The syringe draws out about 100mL of cleaning solution, and then purges and rinses several times.

Note: If there is salt precipitation or dirt attached to the Rinse port nut, the injection port liner, and the injection port nut, first use pure water, then ultrasonic ultrasonic cleaning with isopropyl alcohol or methanol for 10 minutes. Wash off the dirt and dry before installing.

6. Replace the metering pump sealing gasket promptly

Replace the sealing gasket of the metering pump in time: When replacing the sealing gasket at this position, please note that unlike the pump, the user must first enter the diagnostic maintenance interface of the instrument, retract the plunger rod in the metering pump, and then disassemble the metering pump, otherwise When removed, the plunger rod is in a compressed position, which makes installation troublesome. The frequency of use of the metering pump is very low, almost negligible, but the sealing gasket will also wear out. Instruments that have been used for three to five years will sometimes find leakage at this location, but the frequency of this problem is very low.

7.Through valve maintenance

The injection speed should be fast. A flat-tipped needle must be used for syringe injection. When using the partial filling method for sample injection, the injection volume is usually 75% of the volume of the quantitative tube. If the 25µL quantitative tube is used to inject 15µL more, and the volume of each injection is required to be accurate and the same; generally do not disassemble the valve body easily. , the valve can only be opened if the hole has been blocked or if worn parts need to be replaced. All sample solutions must be filtered with a 0.45µm filter to prevent particles from clogging the injection valve and reduce wear on the injection valve. Clean the injection valve frequently. When the gas chromatograph is not used for a long time or the ambient temperature is high, the solution in the eluent remaining in the valve will volatilize and the salt concentration will increase to form crystallization.

Back to List

-

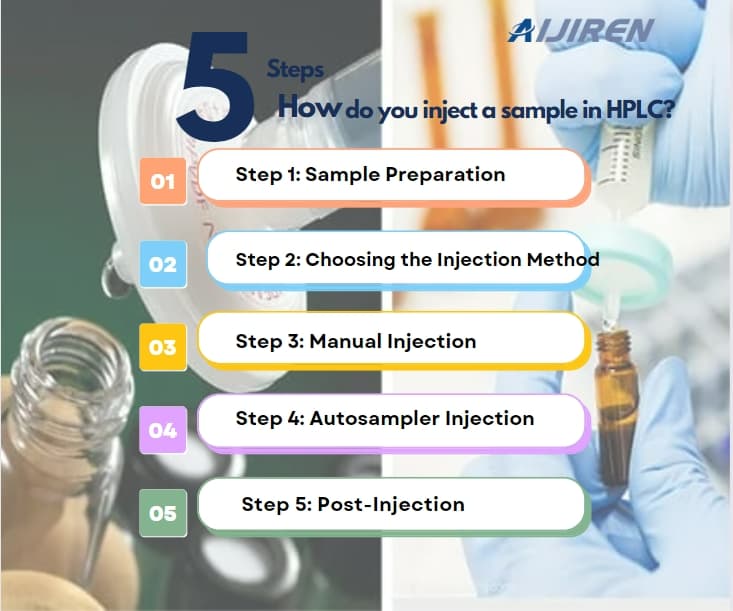

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

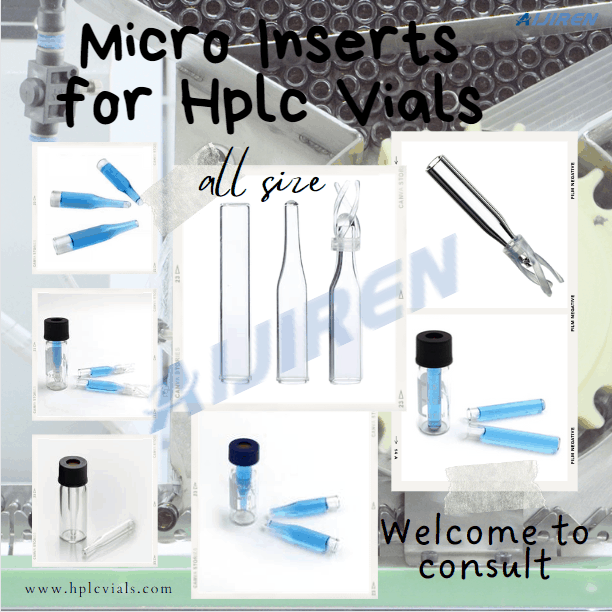

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

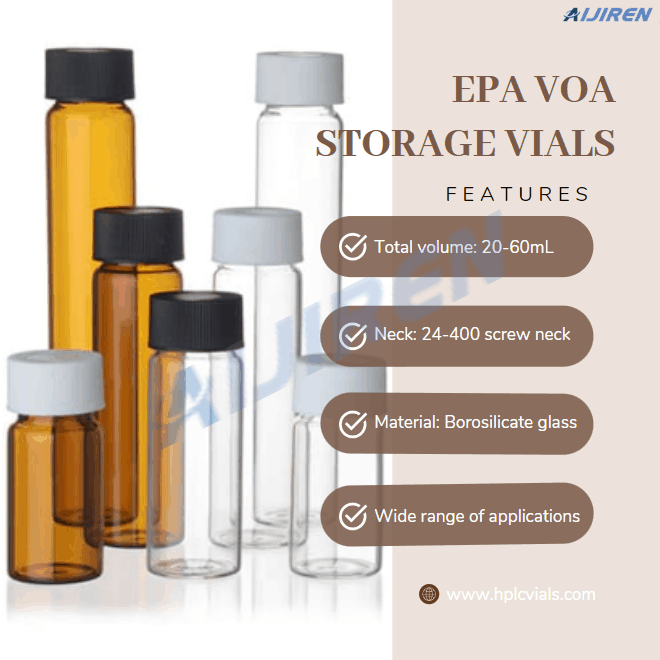

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines