One of the “Three Key Points” for HPLC Instrument Operation: Rinsing

The third key to keeping your HPLC system running well is to keep the system clean. You need to pay attention to all the places where the mobile phase flows through the system. Frequent rinsing of these areas will keep your system in a “ready” state.

1. Mobile Phase Storage Bottle

First of all, clean the mobile phase storage bottle frequently or replace the mobile phase each time a new batch of samples is prepared. A dirty storage bottle will contaminate the injected mobile phase. It is recommended that the buffer solution in the storage bottle be used for no more than one week and the organic solvent for no more than one month. Some people also suggest keeping the storage bottle filled with solvent until the analysis method storage bottle needs to be replaced with a new solvent (the composition of the mobile phase changes). It is better to pour out the old solvent and replace it with a new one. This is better than running out of solvent. However, this may seem wasteful for laboratories analyzing small sample volumes. Instrument company engineers recommend changing the water in the water storage bottle every day and cleaning the bottle with isopropyl alcohol once a week. Some laboratories add 0.1 to 1 mM formic acid to the water to inhibit the growth of microorganisms. These methods may seem a bit cumbersome, but they can play the role of “sharpening the knife without chopping the wood”.

2. Pump

The pump must be rinsed next. Never stop the pump a few minutes after analysis, especially if the mobile phase contains a non-volatile buffer (such as phosphate). If the instrument is not used continuously, when the mobile phase evaporates, the refractory substances will stick to the surface of the piston seal and the refractory substances will form solid precipitates. This is one of the major causes of pump seal wear and check valve leakage. Therefore, the pump must be flushed with unbuffered mobile phase for more than half an hour before stopping the pump, regardless of the duration of use. If there is a non-volatile buffer salt in the mobile phase, it is recommended that the flush time be longer.

3. Autosampler

The autosampler must also be cleaned according to regulations. Most current instruments are equipped with autosampler rinsing fluid bottles. Usually, the only thing that needs to be done is to replace and replenish the rinsing fluid in a timely manner. The wash liquid used in the autosampler should also be treated in the same way as the mobile phase, and the liquid storage bottle should be cleaned or the wash liquid replaced according to the expiration date and regulations of the solvent. Today’s autosamplers are very easy to set up and operate. If time permits (especially when running at night), it is also a good practice to set up 1 or 2 injections of pure solvent (such as methanol, acetonitrile) after each analysis.

4. Chromatographic Column

Column contamination increases over time. The usual symptoms are: when running the baseline, the baseline noise in the recorded chromatogram increases and the pump pressure also increases. The most effective way to solve this problem is to rinse the column with a large amount of mobile phase (e.g. methanol, acetonitrile and water) after each batch of samples or when preparing to unload the column. It is better to use a gradient wash. The specific ratio depends on the instructions and the characteristics of the column.

5. Detector

In normal use, the detector is cleaned according to its type and instructions. For example, for UV/VIS or FL detectors, contaminants in the detector flow cell are also cleaned when the column and system are rinsed. However, evaporative light detectors or mass spectrometers must be cleaned regularly according to the instructions. These detectors will have hard-to-volatilize contaminants deposited during use, such as the spray needle, capillary tube, cone orifice plate, pre-quadrupole, and other components of the mass spectrometer ion source, so they must be cleaned regularly. In addition, it is best to disconnect these detectors when flushing the system to reduce contamination of the detectors.

In short, if the liquid chromatograph used daily in the laboratory can carefully perform these three tasks – degassing, filtering, and rinsing – your instrument will receive good preventive maintenance and be more comfortable to use. Of course, the problems encountered in actual operation are not that simple, but these three good habits will be the basis for correct operation and use of the HPLC system.

Back to List

-

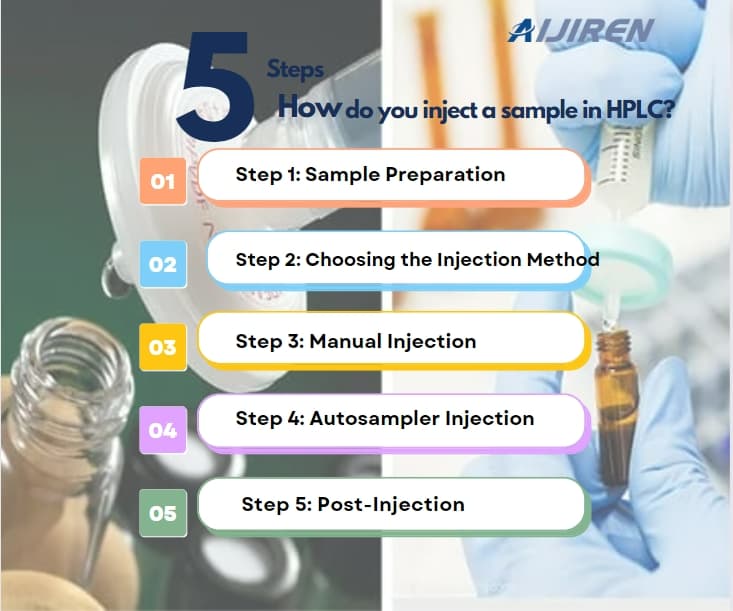

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

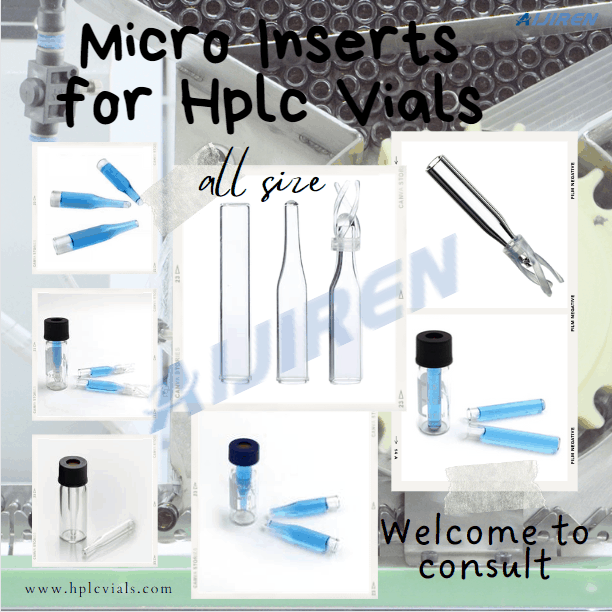

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

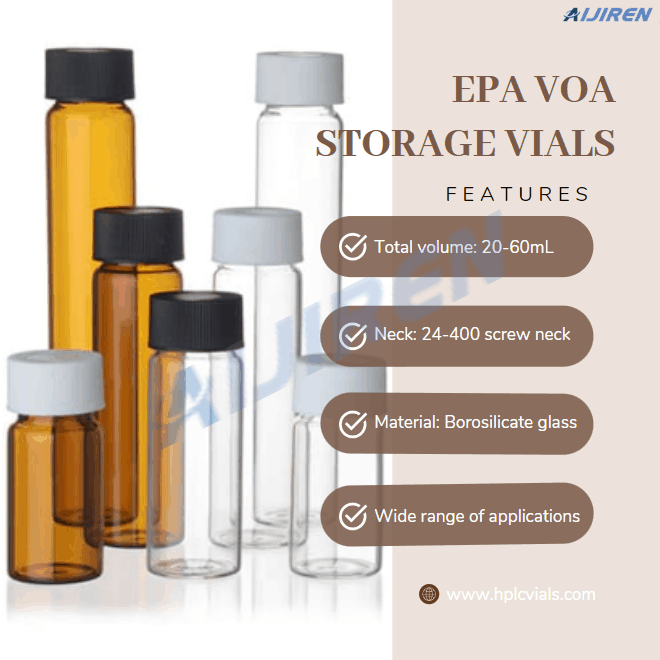

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines