Analysis and treatment methods of causes of chromatographic peak tailing(Ⅱ)

Last time we explained the causes of liquid chromatography column tailing. Today we will explain the causes of gas chromatography peak tailing.

Generally speaking, when dealing with gas chromatography peak tailing problems, it can be summed up in one sentence: XXX sample is tailing on XXX chromatographic column. What is the reason?

GC peak tailing

1. Active ingredient tailing

Polar or reactive compounds are easily adsorbed by active sites in the sample flow path and appear tailing. The analysis of such samples requires a system with good inertness.

On the one hand, it is necessary to maintain the cleanliness of the system (mainly the inlet and column) and use clean liners and split plates.

For severely contaminated chromatographic columns, the injection port end can be cut off by 0.5 to 1 meter. If the contamination is serious, more can be cut off or the column can be thoroughly cleaned with solvent (it must be a cross-linked bonded stationary phase).

On the other hand, more inert consumables should be selected, such as deactivated liners (glass wool is not used or used with caution) and low-bleed chromatographic columns with good inertness.

Proper column installation is also important

If it is a capillary column, the chromatographic column should be cut smooth and smooth. The remaining burrs or debris will be potential active sites, which can easily cause the adsorption and tailing of active components;

Note that the extension distance of the chromatographic column in the FID/NPD nozzle should not be too short, because the active components may be adsorbed by the metal tube wall of the nozzle and tailed.

In short, according to the principle of similarity and compatibility, there will be active sites in various parts of the gas chromatography flow path instrument, which will easily adsorb active components, causing the chromatographic peaks to be easily tailed or even not peaked.

If you want to eliminate this effect, you can choose deactivated or inert inlet accessories and chromatographic columns to eliminate active sites on the flow path.

2. Volatile component tailing

The tailing of early eluting components is severe, which often occurs when splitless injection, on-column injection, or when the sample solvent does not match the polarity of the chromatographic column. This is mainly caused by insufficient solvent focusing effect.

To improve the peak shape, you can use a retention gap column (a 3-5 meter deactivated empty column connected in front of the analytical column), lower the inlet temperature by 50°C, and adjust the temperature program to make the initial temperature lower than 10~25°C of the boiling point of the solvent.

It should also be confirmed that there is no air leakage after the chromatographic column is installed, and there is no dead volume at the connections of the system.

3. Low volatile component tailing

Tailing peaks are mostly chromatographic peaks that elute later, and tailing tends to intensify as retention increases.

In addition to checking whether there is contamination in the system, attention should be paid to eliminating condensation points and appropriately increasing the temperature of the inlet or detector, chromatographic column, transfer pipeline, etc.

It may also be caused by the dead volume of the system. Check transmission line connectors or fused silica connectors to reduce dead volume.

4. All components are trailing

The main reasons include:

The inlet/chromatographic column is seriously contaminated;

The split ratio is too low;

Improper installation of the chromatographic column (for example, in the split/splitless inlet, the distance between the chromatographic column and the sealing gasket should not exceed 4~6 mm. Excessive probing will prevent the sample from entering the chromatographic column quickly and effectively, thus causing peak tailing.) The distance between the capillary column and the nozzle of FID/NFD/FPD is too short, and all peaks may be tailed.

5. Other possible reasons for peak tailing

• In non-split mode, the delay time is too long (usually should be between 0.5~1.0 minutes)

• There is sample residue in the syringe during injection

• Insufficient detector makeup gas flow

• PLOT column overload

• Components co-elute

• Poor injection technique

Some phosphorus-containing compounds will show tailing peaks on NPD white rubidium beads. It is recommended to replace them with black rubidium beads.

Many chromatographic peak shape problems are compound problems and are not necessarily caused by the chromatographic column. When encountering abnormal peak shapes, you need to patiently investigate them one by one to solve the problem.

Back to List

-

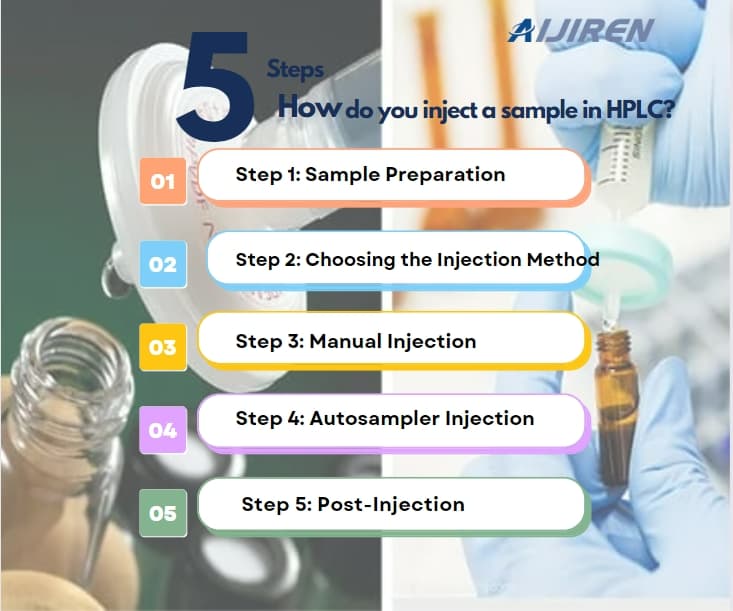

下午2:56How do you inject a sample in HPLC?

下午2:56How do you inject a sample in HPLC? -

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique

上午9:04How Chromatography Empowers Drug Detection: A Powerful Analytical Technique -

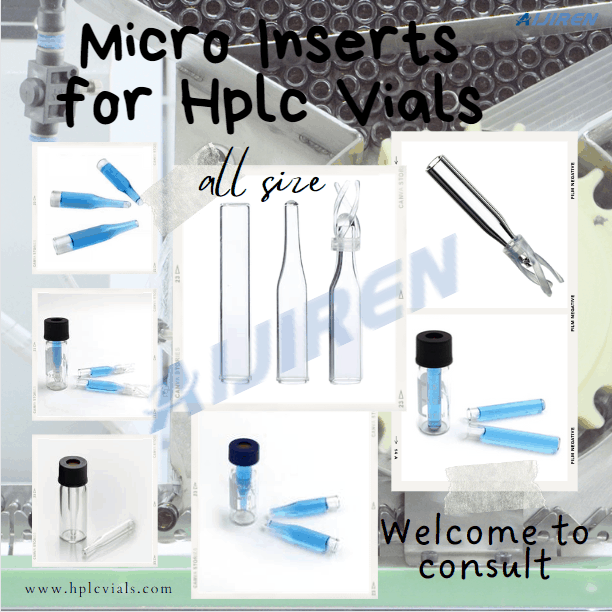

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午5:14Common faults and solutions of automatic samplers(1)

下午5:14Common faults and solutions of automatic samplers(1) -

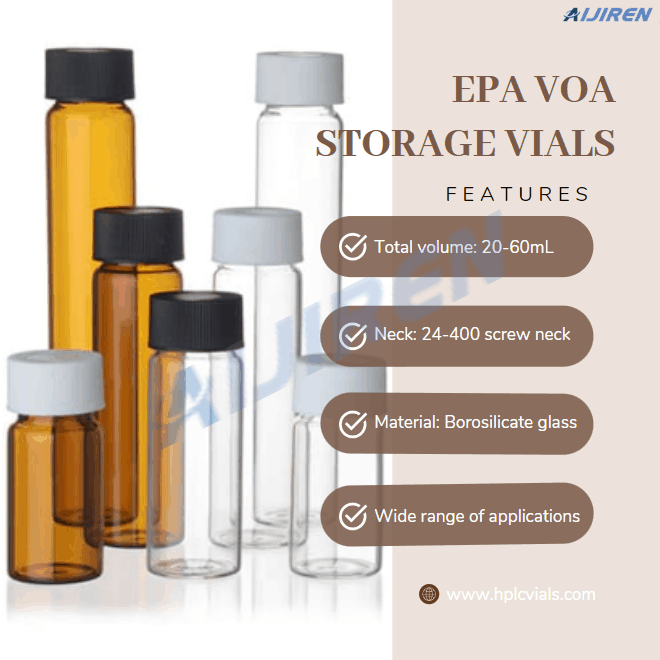

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines